Warehouse and Storage Facilities

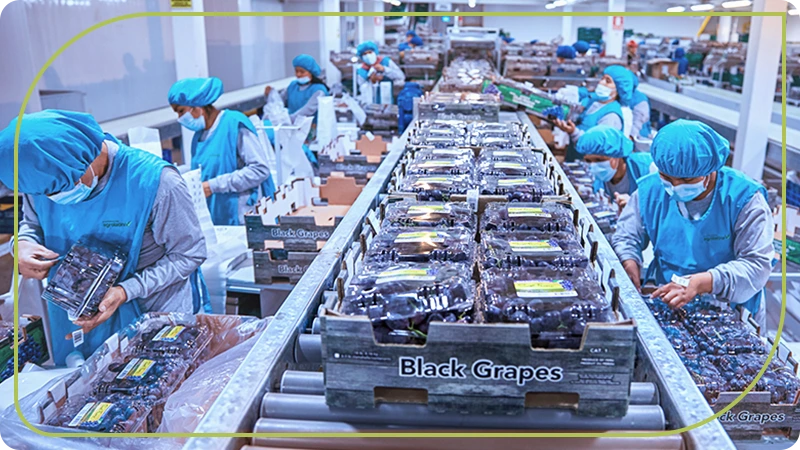

Since building our packing plant in 2008, Agrolatina has quickly become a leader in Peru’s fruit export industry, processing up to 1,000,000 kilos of patented table grapes daily, along with avocados and pomegranate arils. Our facility is equipped with state-of-the-art digital tools and advanced cooling systems, allowing us to ensure precision and care in every step of the packing process.

We carefully control temperature and humidity to maintain the highest standards of quality and freshness throughout. Backed by a highly trained team, we are dedicated to delivering premium fruit from harvest to table, ensuring that each product reaches our customers in optimal condition.

0

kg.

Pomegranates - Daily processing capacity

0

m2

Total Plant Area

0

kg.

Grapes - Daily processing capacity

0

pallets

Cooling tunnel

0

kg.

Avocados - Daily processing capacity

0

pallets

Storage chamber